BUSINESS

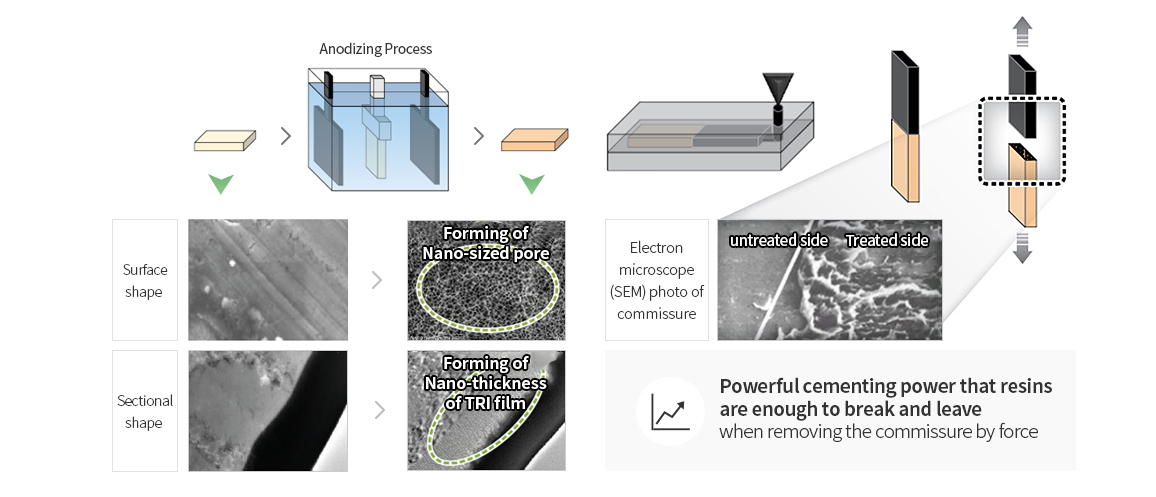

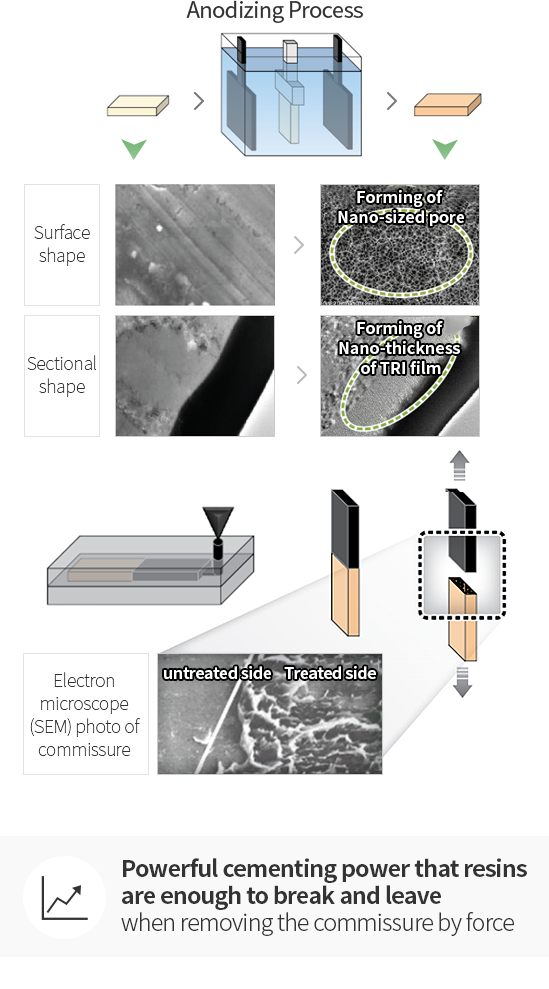

What is TRI System?

It is our own technology securing powerful cementing power and airtightness through bonding with resins on metal by forming TRI film. GEO Nation is focusing on market commercialization and on securing technology development through exclusive alliance with Japanese TOADENKA.

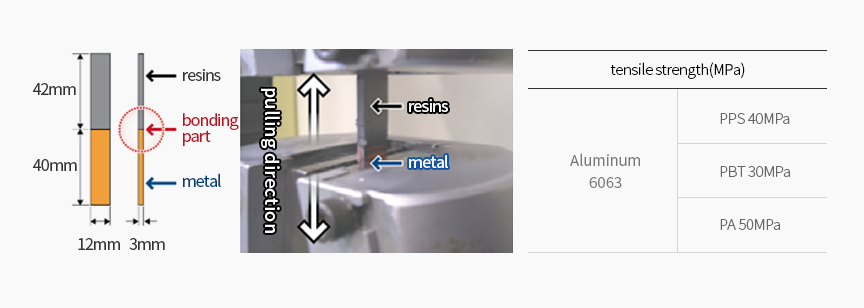

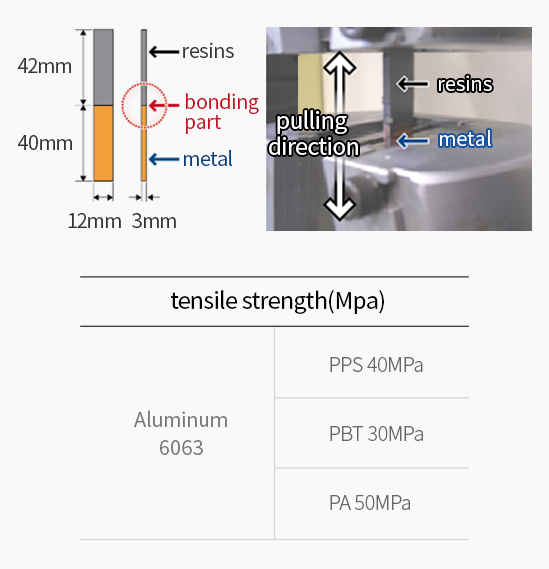

Features of TRI System Technology

Excellent bonding strength

The metal and resins are bonded by bonding film formed on the metal surface with the TRI-System. The excellent bonding strength cannot be compared to bonding among molecules of adhesive. / resins/bonding part/metal/pulling direction/tensile strength

High airtightness

High airtightness can be maintained because the metal and resins are bonded evenly.

-

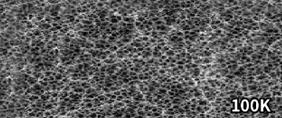

TRI film is generated evenly on the surface of metal in TRI treatment

The resins are left evenly in breaking the bonding side after injection)

-

Etching method irregularly generates holes on the surface of metal.

The resins are irregularly spread in breaking the bonding side after injection

Helium Leak Test

1. to inspect exactly water repellency by using He (Helium gas) atom which is smaller than molecule of water.

2. Amount of leakage: less than 9x10·10 P a·m3

-

TRI treated (aluminum) film surface

FE-SEM image -

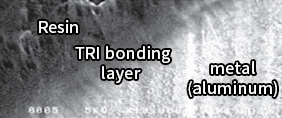

Aluminum-PPS bonding interface

FIB-SEM image

(TRI bonding layer / metal aluminum)

High reliability

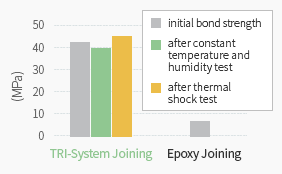

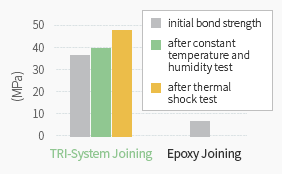

< Tensile stress data of AL & PPS >

-

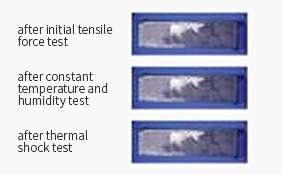

Tensile strength test after reliability test

-

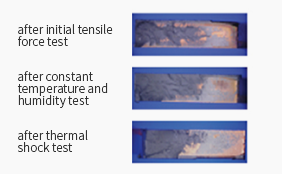

fracture surface of metal layer after tensile force test

< Tensile stress data of Copper & PPS >

-

Tensile strength test after reliability test

-

fracture surface of metal layer after tensile force test

< Reliability test conditions >

- constant temperature and humidity: 80˚C. 95%, 200hours

- thermal shock: 80˚C, 30minutes ↔ -40˚C, 30minutes, 150cycles

High Yield Rate

| Condition | Injection right after treatment |

Injection 30days later (40℃ / 50%) |

|---|---|---|

| Initial Tensile Stress TEST |  |

|

| Hum’ & Tem’ Test |  |

|

| Thermal shock |  |

|

| Condition | Tensile Strength Data (MPa) | Remarks | ||||

|---|---|---|---|---|---|---|

| Temp-eraturen | Humid | Lag time | Initial Inject. | Hum’&Tem’ | Thermal Shock | |

| Injection right after TRI treatment | 43 | 42 | 46 | Basic condition | ||

| 40 | 50 | 30 | 40 | 38 | 45 | Summer condition |

* Test performed 30days later after TRI treated

Possible materials for TRI System bonding

Total bonding of metal

and resins

| category | tensile force | He leak | high temperature and humidity | thermal shock | MPa |

|---|---|---|---|---|---|

| copper(Cu) | 25~35MPa | OK | 25MPa | 25MPa | under mass-production |

| aluminum(Al) | 35~45MPa | ||||

| stainless steel(SUS) | 30~40MPa | Completion of development | |||

| titanium(Ti) | |||||

| iron(Fe) | |||||

| magnesium(Mg) |

- constant temperature and humidity: 80℃, 95%, 200hours

- thermal shock: 80℃, 30minutes ↔ -40℃, 30minutes, 150cycles

- grade of resin, The bonding power could be different by difference of mixed compound.

- Materials besides above metals and resins are possible to bond after development and study.

Resins possible to bond

| category | PBT | PPS | PA | PPA | TPE | TPU | PCT | PET | PEEK | PP |

|---|---|---|---|---|---|---|---|---|---|---|

| bonding possibility |

- applicable material : AI

TRI System applicable areas

- TRI SYSTEM

- World Best Technology

- Metal & Plastic

- Convergence

5H

- High Demands

- High Reliability

- High End Technology

- High Cost Down

- High Satisfaction

mobile

smart devices

automobile area

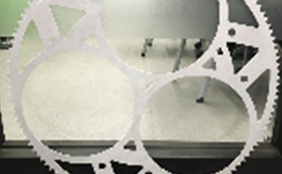

development case of Ultra Capacitor of Honda Auto

Lithium-ion battery Module for automobile

- high pressure water-resistance, durability and high strength bonding

- miniaturization, cost saving, productivity enhancement

other cases

-

high airtightness connector

-

radiation of heat, insulated parts

-

parts of digital camera

-

parts of machine (grinder and so on)

Quality guaranteed Equipment status

GEO Nation Vietnam makes the best efforts for quality guarantee with diverse measuring instruments and reliability equipment.

1. Tensile force tester

max. load: 1,000Kg

2. Helium leak tester

-

3. Thermo-hygrostat

Temperature range : -40~150℃

4. Thermal shock tester

Temperature range : -60~150℃

5. Salt water spray tester

Chamber (RT ~ 35℃),

Saturation Tank (RT ~ 60℃)

6. Rubbing tester number of axis

Number of axis :3 axes

7. UV Rays tester

UV-V Type, 15W

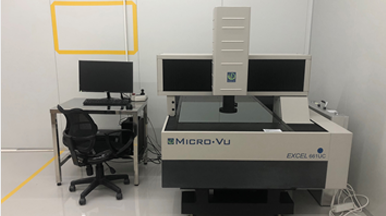

8. 3D measuring instrument (non-contact)

Measuring domain : 600 X 500 X 440㎜

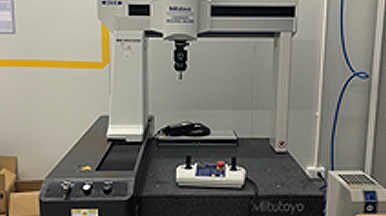

9. 3D measuring instrument (contact)

measuring domain : 615 X 615 X 160mm

10. VISION measuring instrument

Measuring area : Ø100 X 200mm

11. 3D measuring instrument (non-contact)

Measuring area : 300 X 200 X 300mm

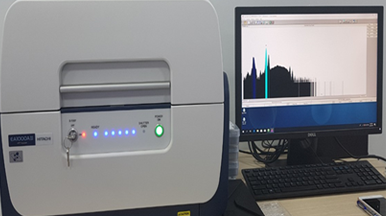

12. XRF measuring instrument(contact)

X-ray Tube (Rh Target)

Voltage : Max 50Kv